Making Circuits

robinmitchell2024-07-18T19:58:27+01:00Making Circuits

Breadboards

Breadboards are a makers first solution for prototyping circuits as they do not require soldering, allow for components to be easily reused, and are extremely configurable. However, they are also not suitable for final designs, and they can be somewhat challenging to use at time. In this guide, learn what breadboards are, how they work, and how to use them.

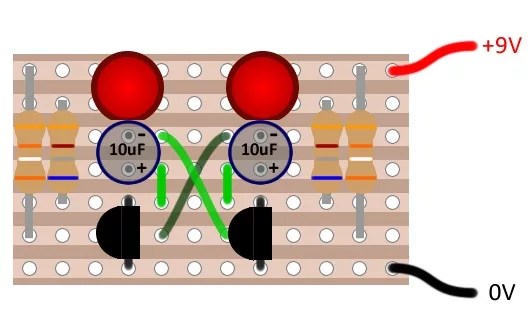

Stripboards

Makers and engineers who want to bring their design to the next level can consider using stripboards, which sit in between breadboards and PCBs. While they require solder (making them permanent builds), they are still far easier to configure than PCBs, and their low cost and matrix design makes them excellent for prototyping circuts that need to be tested in real-world application. In this guide, learn everything there is to stripboards, when to use them, and when to move onto PCBs.

Printed Circuit Boards (PCB)

Printed Circuit Boards (PCBs) are the final design choice for engineers, and the only way to make circuits for use in mass production environment. While PCBs are expensive, difficult to design, and nowhere near suitable for prototyping, you will eventually want to get your own PCB made up as they are the best way to create a permanent design. In this guide, learn how PCBs work, when to use them, and numerous design tips that will ensure maximum success.