In a recent breakthrough, a South Korean research team, under the leadership of Director Jo Moon-Ho, has developed a groundbreaking technique that allows the creation of "one-dimensional" metallic nanomaterials with widths as small as 0.4 nanometers. This innovation has the potential to revolutionize semiconductor and nanomaterial technology, offering new possibilities for ultra-miniaturized semiconductors. By overcoming traditional lithography limitations in semiconductor fabrication, the team has opened up avenues for the development of high-performance electronic devices in the future. How might the creation of "one-dimensional" metallic nanomaterials impact the semiconductor industry, what challenges did the team face in integrating 2D semiconductors into devices, and how could this breakthrough influence the production of high-quality 2D materials on a large scale?

As the world enters a new era of semiconductor development, one fact remains true for the past 50 years; transistors will only get smaller. The guidance of Moore’s Law has seen transistor sizes shrink exponentially, doubling every two years, resulting in devices that are faster, more powerful, and smaller than ever. However, as transistors approach the atomic scale, physical limitations now hinder further shrinkage, raising concerns about the future of semiconductor manufacturing and whether Moore's Law will continue to hold true.

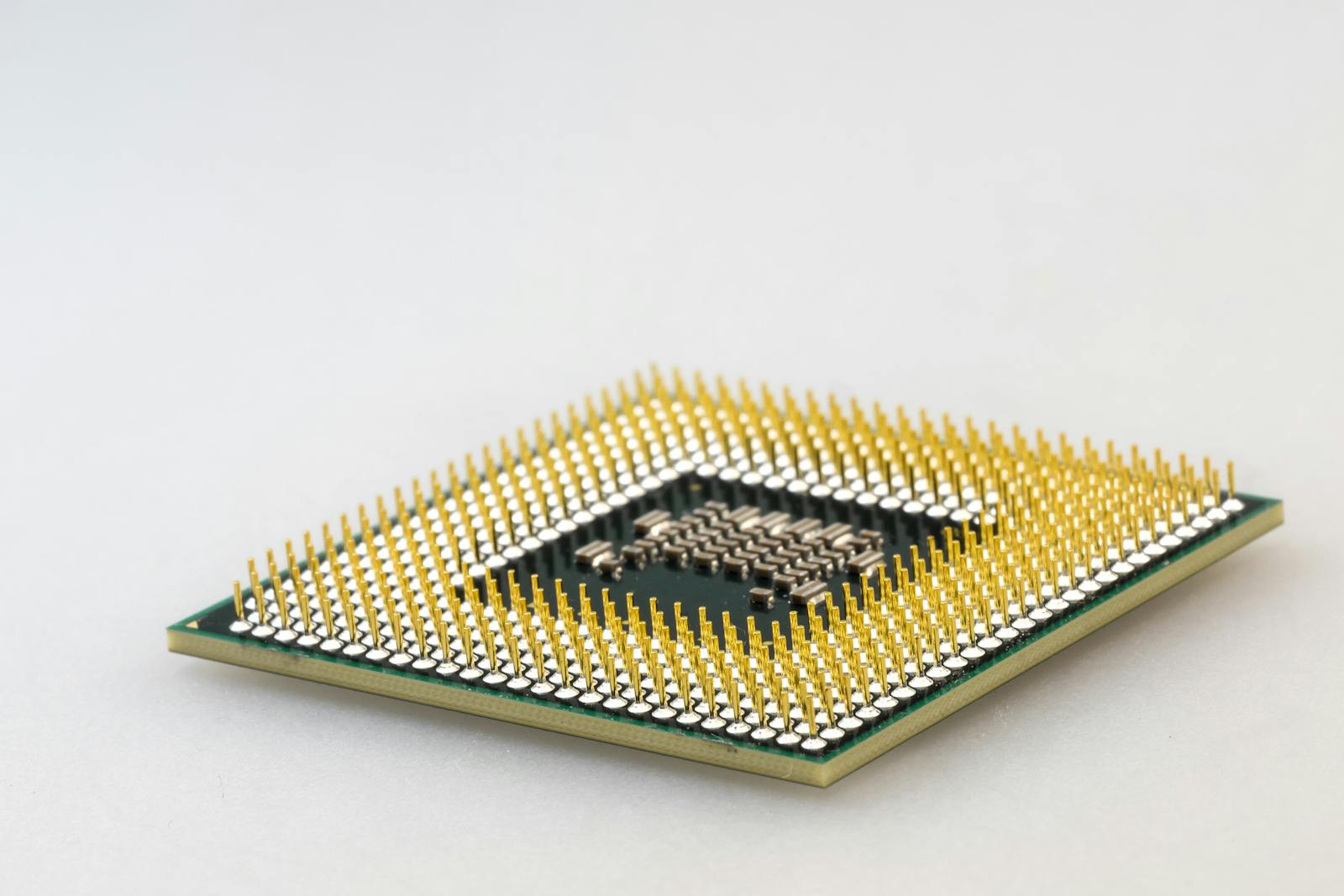

One of the primary challenges faced is the reliance on traditional lithography to fabricate integrated circuits. The process of exposing a photoresist with a mask featuring the design is only the first step, with the resulting mask then being exposed to different chemicals to create either an etched design or an exposed design. However, as transistor features approach the subnanometer mark, accuracy and precision become increasingly critical, making it difficult to achieve uniform results across entire wafers.

The inability to achieve uniformity also affects transistor performance, with variations in gate electrode width and control efficiency directly impacting the functionality of devices. The gate electrode plays a pivotal role, as it regulates the flow of current through the transistor by controlling the gate voltage. A smaller gate electrode, for example, can exhibit better performance due to faster charge carrier movement, but such transistors also have lower on-off ratios, reducing their overall efficiency. Thus, industry experts are advocating for gate electrodes that are neither too large nor too small, but finding this sweet spot is not easy to achieve.

The semiconductor industry must address these challenges to ensure the continued success of Moore's Law and achieve further miniaturization of transistors. Researchers are exploring new lithography techniques, such as extreme ultraviolet (EUV) lithography, to improve accuracy and precision at nanometer scales. Additionally, advances in gate technologies, such as channel body contacts and multi-gate designs, are being developed to enhance transistor performance and efficiency.

As the industry navigates these hurdles, the future of semiconductor development holds promise, with the potential for continued advancements in transistor technology and the eventual realization of 1nm devices. However, the slowdown of Moore's Law also highlights the need for the industry to look beyond transistor size as a metric for advancement, with the emergence of 3D devices and systems-on-chip offering new opportunities for growth and innovation.

The road ahead will be paved with new technologies, innovative solutions, and breakthroughs, as the industry confronts the physical limitations of transistor miniaturization and works towards the next generation of semiconductor devices.

In the relentless pursuit of smaller and faster electronic devices, a team of researchers from South Korea has achieved a major feat in the creation of one-dimensional metallic nanomaterials with widths as small as 0.4 nanometers. Led by Director Jo Moon-Ho, the team's innovative technique surpasses the limitations of traditional lithography, paving the way for the transformation of semiconductor and nanomaterial technology.

The researchers utilized monolayers of molybdenum disulfide in their study, exploiting the mirror twin boundary of this material as a 1D metal gate electrode. This strategic approach unlocks the full potential of monolayers in the creation of one-dimensional conductors, a critical component for nanodevice fabrication.

The team's investigation of gold nanotriangles also played a crucial role in their research, shedding light on the interactions between conductors and semiconductors at the nanoscale. The use of gold nanotriangles enabled the researchers to gain a deeper understanding of the mirror twin boundary of molybdenum disulfide, a key to unlocking the properties of one-dimensional metallic nanomaterials.

This breakthrough of one-dimensional metallic nanomaterials by the South Korean research team ushers in a new era of device creation, with the potential to enhance transistor efficiency and performance. The team's innovative approach sets the stage for the advancement of low-voltage, high-speed electronic devices, a crucial step towards achieving the ultimate transistor.

The use of metallic nanomaterials as gate electrodes on 2D substrates offers a potential solution to the challenges faced in scaling up the production of high-quality 2D materials. As such, this potential manufacturing method could enhance the production of high-performance electronic components, setting the stage for the creation of ultra-miniaturized, low-voltage devices.

However, this groundbreaking research also has a number of real-world implications for the future of electronic device production. For example, the team's achievement in growing metallic nanomaterials for use in nanocomponents could lead to the development of advanced electronic systems that are smaller, faster, and more energy-efficient. The use of these nanomaterials in electronic devices would then allow for the creation of ultra-compact, high-performance components, revolutionizing the field of electronics and propelling the industry towards new frontiers.

The achievement by the South Korean research team signifies a major step forward in the pursuit of miniaturizing electronic devices. The successful application of metallic nanomaterials in semiconductor production opens up new avenues for enhancing the efficiency and performance of electronic components, paving the way for the advancement of electronic technology into the future.