Intel's latest move to utilize the TSMC 4 nm process for the upcoming Arc Xe2 Battlemage GPUs marks a significant shift in their graphics architecture strategy. With the promise of enhanced performance and efficiency, this decision is poised to make the "Battlemage" a strong contender in the GPU market. What challenges have manufacturers faced with transistor sizes approaching the single nanometer, what specific improvements in transistor density and energy efficiency can users expect from this strategic move, and how will Intel's new development and use of 4nm technology help consumers?

The relentless pursuit of shrinking transistors has been the backbone of the semiconductor industry's remarkable advancements, thanks to Moore's Law predicting the doubling of transistors on a microchip every two years. This exponential growth in computational power and device efficiency has transformed how we live and work, with computing systems becoming the backbone of modern life. However, as transistor sizes approach the atomic scale, new challenges emerge, posing significant hurdles to further reducing the size of transistors.

One of the critical challenges that arise when transistors reach the nanoscale is the issue of reliability. Smaller transistors are more prone to quantum tunneling, leading to leakage current and, consequently, poor performance. Maintaining transistor integrity and ensuring reliable logical states becomes a major challenge when working with such tiny structures. The inherent physical limitations of the nanoscale require engineers to develop advanced manufacturing processes and innovative design strategies to overcome these quantum effects and produce reliable transistors.

Furthermore, the tight packing of transistors on a chip generates significant heat, compromising the performance of electronic devices. Innovative cooling techniques and materials are essential to efficiently remove the excess heat without compromising the delicate structure of the transistor. The close proximity of transistors in the nanoscale raises concerns about heat dissipation, as the high density of transistors can result in thermal hotspots that can damage sensitive electronic components. Researchers and engineers are exploring new cooling solutions to mitigate this heating effect and optimize transistor performance.

However, the need to balance heat dissipation with transistor size reduction introduces a trade-off in semiconductor design. With the space between transistors being reduced, cooling efficiency suffers, while the increased density of transistors enhances device performance. Finding the ideal equilibrium between these competing factors is crucial to achieve the next generation of technological advancements.

Thus, the pursuit of single nanometer transistors involves overcoming substantial hurdles related to physical limits, heat management, and quantum mechanics. The semiconductor industry must invest in innovative solutions to tackle these challenges, pushing the boundaries of transistor size reduction and enhancing the performance of future electronic devices. As the industry approaches the atomic scale, the complexity of transistor design and manufacturing increases, requiring advanced engineering techniques to ensure the success of future semiconductor technologies.

In a bid to dominate the high-performance GPU market, Intel is set to launch its new Arc Xe2 Battlemage GPUs utilizing Taiwan Semiconductor Manufacturing Company's (TSMC) advanced 4 nm process. This process, previously reserved for key clients such as Apple, marks a major shift for Intel as it moves away from its 6 nm production line for the Arc "Alchemist" series. The adoption of TSMC's 4 nm process signifies Intel's commitment to enhancing the performance and efficiency of its GPUs, paving the way for a new era in high-performance computing.

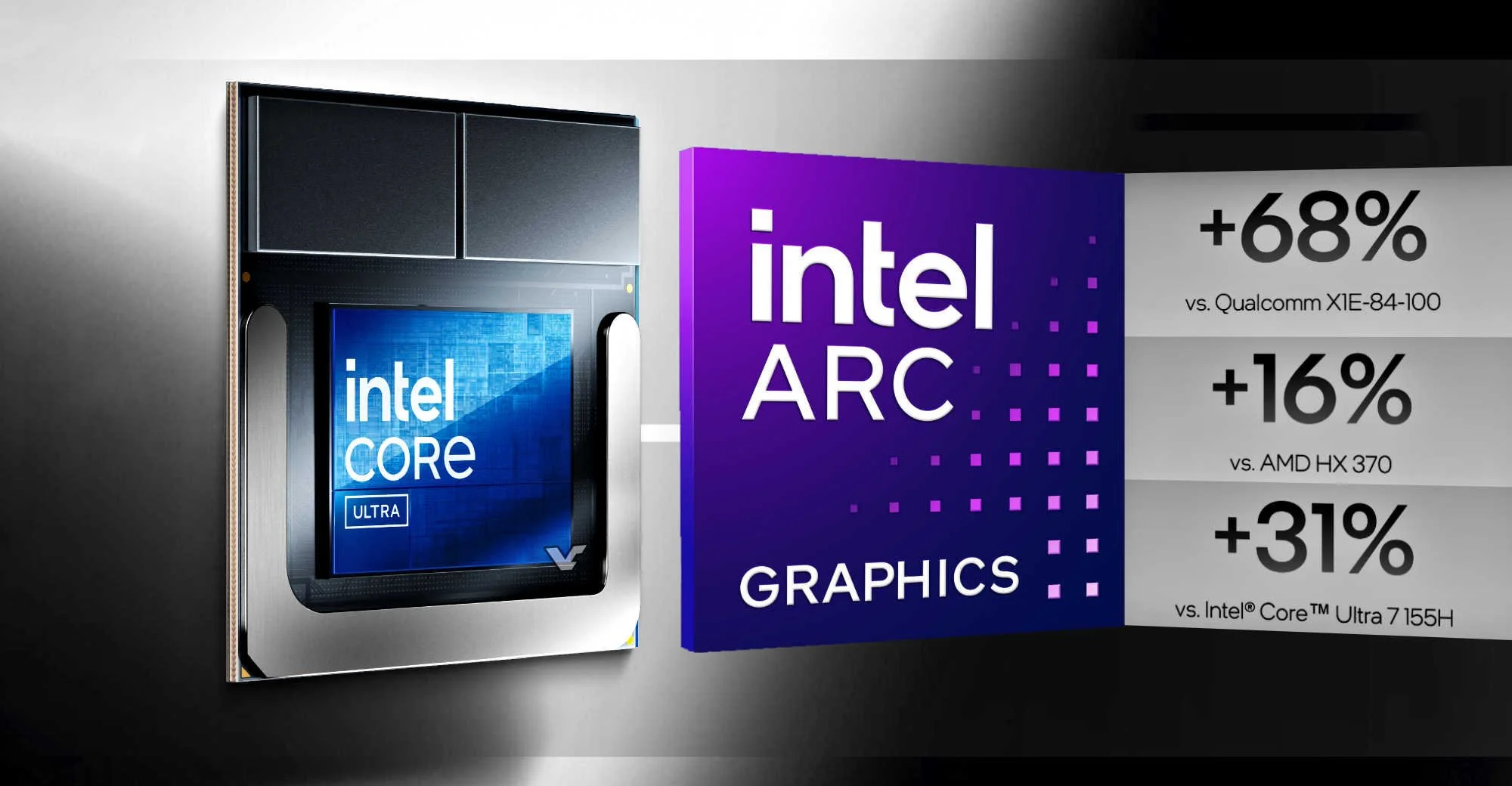

The new Arc Xe2 Battlemage GPUs are expected to feature significantly improved characteristics compared to their predecessors. With the transition to 4 nm, Intel may double the number of Xe cores in its largest GPU models, setting a new benchmark in the industry. Additionally, the GPUs will benefit from better instructions per clock cycle (IPC) and increased clock speeds, placing Intel's Arc Xe2 Battlemage GPUs at a competitive edge against AMD's RDNA 3 and NVIDIA's Ada GPUs.

The architectural enhancements integrated into the new GPUs will further solidify Intel's position in the high-performance GPU market. By focusing on performance and efficiency, Intel is investing in a future-proof design that will cater to the growing demands of the industry. The strategic update underscores Intel's dedication to advancing its GPU technology, ensuring its products remain at par with the latest developments in the field of high-performance computing.

One of the key benefits of the shift to 4nm is the dramatic increase in transistor density. This compact design will enable Intel to nearly double the number of Xe cores in their "Battlemage" GPU variant, leading to substantial improvements in graphics processing and computing capabilities. The enhanced cores will also expedite instructions per cycle and boost clock speeds, setting a new benchmark in the industry. With these advancements, Intel is poised to intensify competition with established giants like AMD and NVIDIA, offering customers a more comprehensive range of high-performance graphics solutions.

The adoption of 4nm technology is not only a significant step towards enhancing Intel's GPUs but also a golden demonstration of the company's commitment to innovation and industry leadership. By leveraging TSMC's expertise in 4nm EUV processes, Intel is investing in a future-proof technology that will set the stage for the next generation of GPUs. This collaborative partnership underscores Intel's dedication to pushing the boundaries of semiconductor technology, driving a new wave of innovation in the field of graphics processing.

Furthermore, the increased energy efficiency of Intel's GPUs, a direct result of the 4nm technology, will have a profound impact on environmental sustainability. By optimizing power consumption without compromising performance, Intel is aligning its technology with consumer preferences for eco-friendly solutions, paving the way for a more sustainable future in the semiconductor industry. The use of 4nm technology will not only reduce carbon emissions but also reduce the overall cost of manufacturing, making high-performance graphics processing more accessible to customers worldwide.

The integration of 4nm technology into Intel's GPUs signifies a new chapter in the evolution of semiconductors. This chapter represents a convergence of performance enhancement, energy efficiency, and environmental sustainability, setting the stage for a future where technology and nature coexist in harmony. The partnership between Intel and TSMC is a testament to the power of collaboration in driving technological advancements and promoting industry growth, marking a new era in the field of semiconductors.