For decades, stripboards have been the preferred solution for makers and engineers alike for quick prototyping of circuits. These humble boards consist of a grid of plated holes and a layer of conductive material on both sides, allowing for easy connections between components. However, traditional stripboards have remained largely unchanged since their inception, with many manufacturers continuing to use outdated materials and manufacturing techniques.

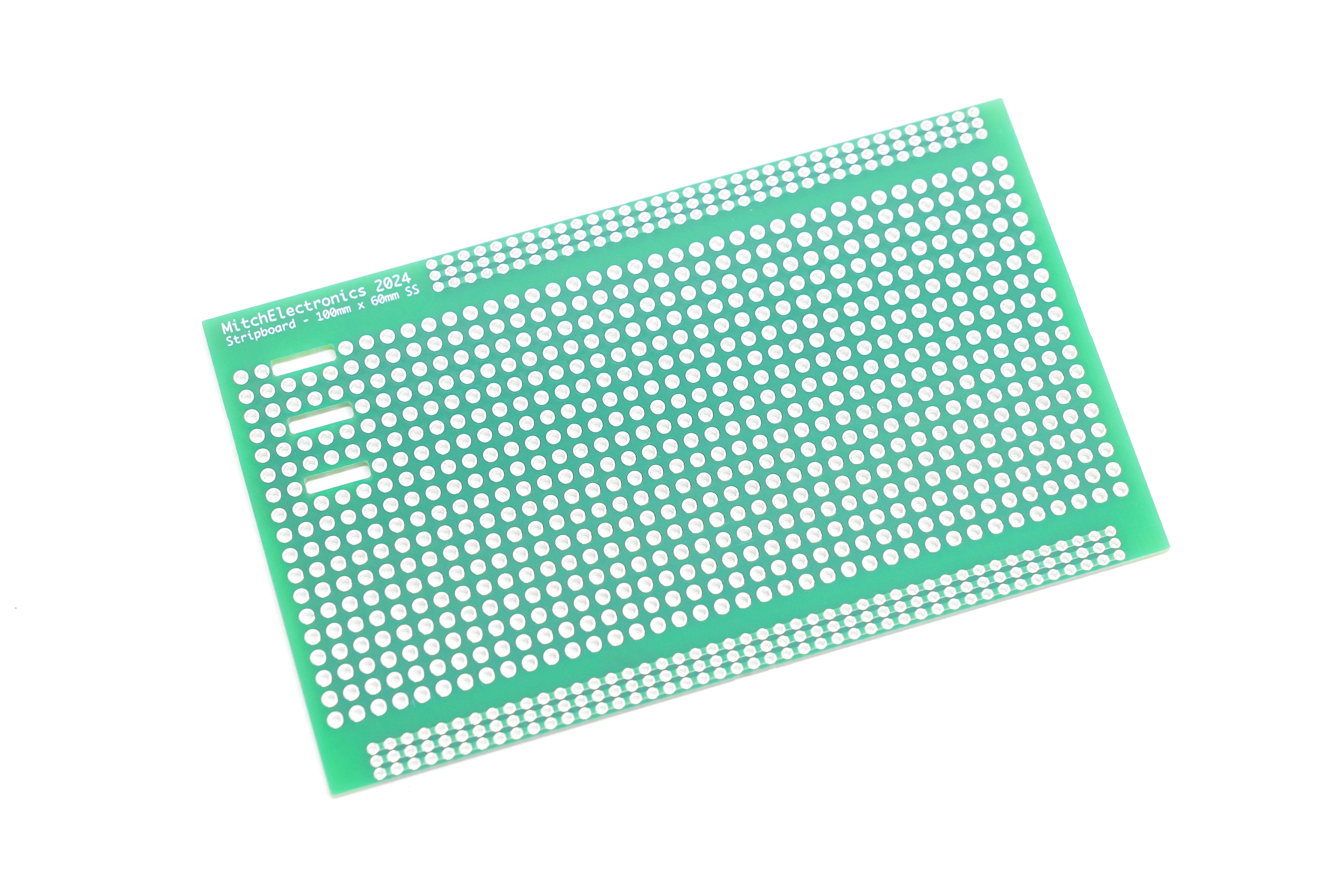

Enter the ME stripboards, a modern take on this classic prototyping tool. Designed and manufactured by Mitchelectronics, these stripboards represent a notable upgrade over their predecessors. Built from solid FR4, a high-quality material known for its durability and resistance to heat and chemicals, the ME stripboards offer a level of quality and reliability that is unmatched in the industry.

One of the standout features of the ME stripboards is their double-sided through-hole plating. This feature means that components can be mounted on both sides of the board, greatly increasing the number of possible connections. Additionally, the use of double-sided plating provides a more robust connection between components, making the ME stripboards ideal for high-current applications.

But the ME stripboards are not just limited to through-hole components. Recognizing the growing importance of surface-mount devices (SMDs) in modern electronics, the ME range also includes SMD stripboards. These boards feature a grid of small pads, allowing for the easy mounting of SMD components. This represents a major departure from traditional stripboards, which are typically limited to through-hole components only.

Stripboards have been significant in maker spaces for many years, valued for being straightforward and user-friendly. However, their use presents several issues in modern electronics.

One major concern is the hazardous chemicals involved in their production. Traditionally, stripboards are manufactured from FR1 and FR2, which are composites of paper and formaldehyde. These substances, once deemed acceptable, are now recognized as detrimental to both human health and the environment, contributing to serious health problems such as cancer and respiratory issues, as well as to climate change through the emission of greenhouse gases.

Additionally, stripboards suffer from physical fragility. Composed of a paper-based material, they are easily subjected to bending and warping. This can lead to breakage of the board's traces, complicating handling and increasing the risk of damage during use. The fragile nature of the boards also makes precision soldering difficult, as the traces can easily detach during the process.

Furthermore, stripboards are not suitable for long-term application in electronic projects. While they might serve well for prototypes and testing phases, their inherent fragility disqualifies them from being used in permanent installations where reliability and durability are crucial.

Another limitation is their design. Being single-sided, stripboards waste potential mounting space on the top side, limiting the complexity of the circuits that can be constructed and making it challenging to pursue multi-layer circuit designs.

Finally, the typical 2.54mm (0.1") grid layout of stripboards is a design catered to older DIP components and does not suit the smaller dimensions of modern SMD components. This mismatch makes it problematic to use stripboards for modern electronic designs that incorporate these newer, more compact components.

The ME range of stripboards represents a revolutionary transformation of the traditional stripboard, reimagining what it means to be a stripboard in the 21st century. Designed with modern makers, engineers, and hobbyists in mind, the ME stripboards address key challenges in durability, functionality, and compatibility. Here's how:

One of the most critical challenges with traditional stripboards has been their lack of robustness. ME stripboards are constructed from FR4, a fiberglass-reinforced material that offers superior strength compared to FR1 and FR2. This upgrade ensures the boards can endure the rigors of modern electronics projects, including repeated soldering, handling, and mounting.

Additionally, every ME stripboard is equipped with through-hole plating. This advanced construction feature reinforces the mechanical strength of each hole, virtually eliminating the issue of pad breakage. Makers no longer need to worry about accidental damage when soldering components or reworking circuits.

All ME stripboards are fully compliant with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) standards. These certifications guarantee that the materials used in manufacturing are safe, environmentally friendly, and free from hazardous substances. Furthermore, the stripboards feature lead-free hot air solder leveling, ensuring compliance with global lead-free initiatives while maintaining high solderability and thermal durability.

Another key improvement in the ME range is their ability to withstand higher temperatures. This makes them ideal for use with modern soldering techniques, including those involving lead-free solder, which typically requires higher heat. Makers can confidently use the ME stripboards in demanding projects, knowing the boards will retain their structural integrity and reliability even under high thermal stress.

The ME stripboards offer unparalleled versatility with options for both single-sided and double-sided boards. For simpler projects, single-sided boards are ideal, while the double-sided versions provide the flexibility needed for more complex routing and designs. This variety ensures that makers have the right tools for any project, whether it’s a straightforward prototype or a sophisticated circuit.

The ME stripboards are designed to align perfectly with modern electronic components. The standard range uses a traditional 2.54mm (0.1-inch) spacing, making them compatible with through-hole components and breadboard-style layouts. However, the SMD (Surface-Mount Device) range introduces a game-changing feature: a 1.27mm spacing. This smaller pitch allows the SMD stripboards to work seamlessly with SOIC (Small Outline Integrated Circuit) parts, enabling makers to integrate cheaper and more compact SMD ICs into their designs without the need for adapter PCBs or conversion mounts. This innovation not only saves time but also reduces overall project costs.

Some models in the ME stripboard range include extra features designed to simplify and secure electronics projects. For example, certain boards are equipped with cable tie mount points, which allow makers to securely fasten cables and wires directly to the board. This eliminates the hassle of loose wires and ensures a clean, organized layout, even in complex builds.

In some projects, managing wires and maintaining a clean layout can be a significant challenge. To address this, certain ME stripboards are equipped with dedicated cable tie mount points. These features enable users to secure cables directly to the board, ensuring that wiring remains tidy and stable. This is particularly useful for complex or portable builds where wire management is crucial.

Power distribution is a critical aspect of any circuit design, and running out of connection points for power and ground can quickly complicate a project. Some ME stripboards include high-density power rails with a greater number of holes, providing ample space for multiple ground and power connections. This feature ensures that makers have sufficient connection points for all their components, simplifying power distribution and improving circuit reliability.

While traditional stripboards are primarily designed for through-hole components, ME stripboards bridge the gap between through-hole and surface-mount technologies. Certain models include SMD (Surface-Mount Device) pads, allowing surface-mount components to be integrated directly onto a 2.54mm stripboard. For example, components like the AMS1117 voltage regulator can be easily mounted to provide 3.3V power to a 5V circuit. This versatility eliminates the need for additional adapter PCBs and enables seamless integration of modern SMD components into prototypes.

Routing complex circuits on a single-sided board can be limiting, especially when dealing with intricate designs or high-density layouts. ME stripboards with double-sided tracks offer a solution by providing conductive traces on both the top and bottom of the board. This allows for significantly denser routing, enabling makers to design more compact and sophisticated circuits without compromising on functionality. Double-sided tracks are particularly advantageous for advanced projects requiring extensive connections and minimal space.

Single-Sided Stripboard: This board features conductive tracks on only one side, making it ideal for straightforward designs and simpler projects where components are primarily placed on one side of the board.

2.54mm Grid: The board follows the standard 2.54mm grid spacing, which is compatible with most through-hole components and makes it easy to design layouts without extra adapters or conversions.

Cable Tie Mount Point: Some of these stripboards come with built-in cable tie mount points, allowing you to securely fasten cables and wires directly to the board for a cleaner and more organized build.

High-Density Power Rails (Double-Sided Rails): The inclusion of high-density power rails with double-sided conductive traces gives you more options for power and ground connections. This feature ensures that your power distribution system is robust and that you won't run out of connection points, even in more complex circuits.

Double-Sided Stripboard: Unlike single-sided boards, these boards feature conductive tracks on both the top and bottom, offering significantly more routing possibilities. This makes them perfect for projects requiring more complex connections or compact designs.

2.54mm Grid: Like the single-sided version, the 100 x 60 DS stripboard also follows the standard 2.54mm grid spacing, ensuring compatibility with a wide range of through-hole components.

Power Strips: This version includes power strips on the board, giving you ample space for reliable power distribution throughout your circuit. These strips provide dedicated areas for ground and power connections, simplifying the design and ensuring a stable power supply to all components.

Single-Sided Stripboard: This version is designed for simpler builds, with conductive tracks on one side, optimized for surface-mount devices (SMD) rather than through-hole components.

1.27mm Grid: With a finer 1.27mm grid spacing, this board is specifically tailored for SMD components, particularly useful for parts like the AMS1117 voltage regulator or other small surface-mount devices. This reduces the need for special conversion PCBs or mounting systems, allowing for a cleaner and more compact design.