So, now that you have rightly decided to choose lead-free solder, the next step is to choose a suitable soldering iron. Thankfully for us, the combination of the continuing falling price of electronics and consumerism has generated a wide range of tools that are all cheaply available. Go back a few decades, and a temperature-controlled soldering station was an extravagant expense, but these days, they are cheaply available.

In fact, not only are soldering irons extremely cheap these days, but they often come with a kit that includes all the tools you will ever need to solder your own PCBs. Furthermore, these stations come with proper stands and controls that make it easier and safer to solder. As such, we highly recommend that you pick up a soldering station set from sites such as Amazon, Rapid Electronics, or eBay.

While temperature control itself isn’t entirely important for makers soldering through-hole PCBs, it is very useful to have as it can be used to bump up the temperature of the iron. If a soldering iron is too cold, it won’t be effective at melting solder, but also remember that it’s not just the solder that needs to melt, but the parts being soldered need to be heated up as well, otherwise, the solder won’t stick to them.

Having a higher heat on a soldering iron tip also helps to liquefy lead-free solder, thereby making it easier to use. Again, many have said that a temperature-controlled iron isn’t important, but MitchElectronics very much disagrees with this statement. Of course, an expensive iron isn’t important, heck, our own irons are very cheap units costing no more than £50 each. But when we solder with lead-free stock, we will always increase the temperature to aid with soldering.

Now, be careful when increasing the temperature of your iron, as this will decrease the lifespan of your soldering tip. Most tips are made from a copper core with plating, but extreme heat eventually eats the tip away. When this happens, the tip of the iron will rapidly break down during use, so be sure to have plenty of spare soldering tips!

Just like temperature-controlled soldering irons, many have suggested that the wattage isn’t entirely important, and again, we disagree. The first, and most important fact to note, is that the wattage of an iron doesn’t relate to its temperature, but instead, relates to how much heat the iron holds. To understand why this is important, let’s look at a simple example.

Imagine a heavy iron anvil and a paperclip next to each other. Both can be heated to the same temperature, say, 100 degrees, but while they are the same temperature, the heavy iron anvil takes a lot longer to cool down. At the same time, that anvil could make a lot more things very warm, while the paperclip would instantly loose its heat the moment it is exposed to anything. This thermal mass operates in a similar way to a soldering irons wattage, such that a soldering iron with a larger wattage can give out more heat without losing that heat itself.

The video below demonstrates this concept of thermal mass, with a red-hot ball of nickel easily melting a small reel of solder while losing virtually no heat doing so.

Now, this becomes really important when soldering large areas, large components, and large amounts of solder. An iron with a low wattage (less than 40W) will likely lose a lot of its heat before it is able to solder a very large tab or component, thus, forming cold joints that don’t perform well. However, an iron with a higher wattage (above 60W) will be able to keep soldering without a fall in temperature, and this will allow for large tabs, connections, and components to be easily soldered.

Thus, we always recommend getting a soldering iron that is at least 60W.

When it comes to choosing a soldering iron bit, there are a number of options available, and each option has its own advantages and disadvantages. However, it is common to find that you will work best with a specific bit, regardless of the job, so if a bit is found that provides the best results for your technique, it’s best to stick with that bit.

Generally speaking, there are two main types of soldering iron tip that you will use; a point and a chisel. Point bits, as the name suggest, are bits that come to a point, and these will vary in the size of the point. A needle point is very useful for tiny SMD work, while larger points are good for through-hole parts. Point tips are not able to deliver as much heat to a joint as a chisel, but are excellent for precision work.

A chisel bit has a wide flat edge that is capable of delivering a lot of heat to a large area. This makes chisel bits very useful for soldering large connections, but their wide length can also be used to solder multiple joints simultaneously. However, the large area of a chisel tip makes it less suitable for precision work, as parts of the tip can touch other components and interfere with other joints. Having said that, chisel tips are useful with MitchElectronics kits due to the large size of the PCBs and use of through-hole parts.

Just like any tool, soldering irons need to be kept clean if they are to provide years of use, and this is especially true for soldering iron tips. A tip that becomes too dirty, rusty, or corroded will not be able to solder as well as it could, causing significant frustration when trying to solder.

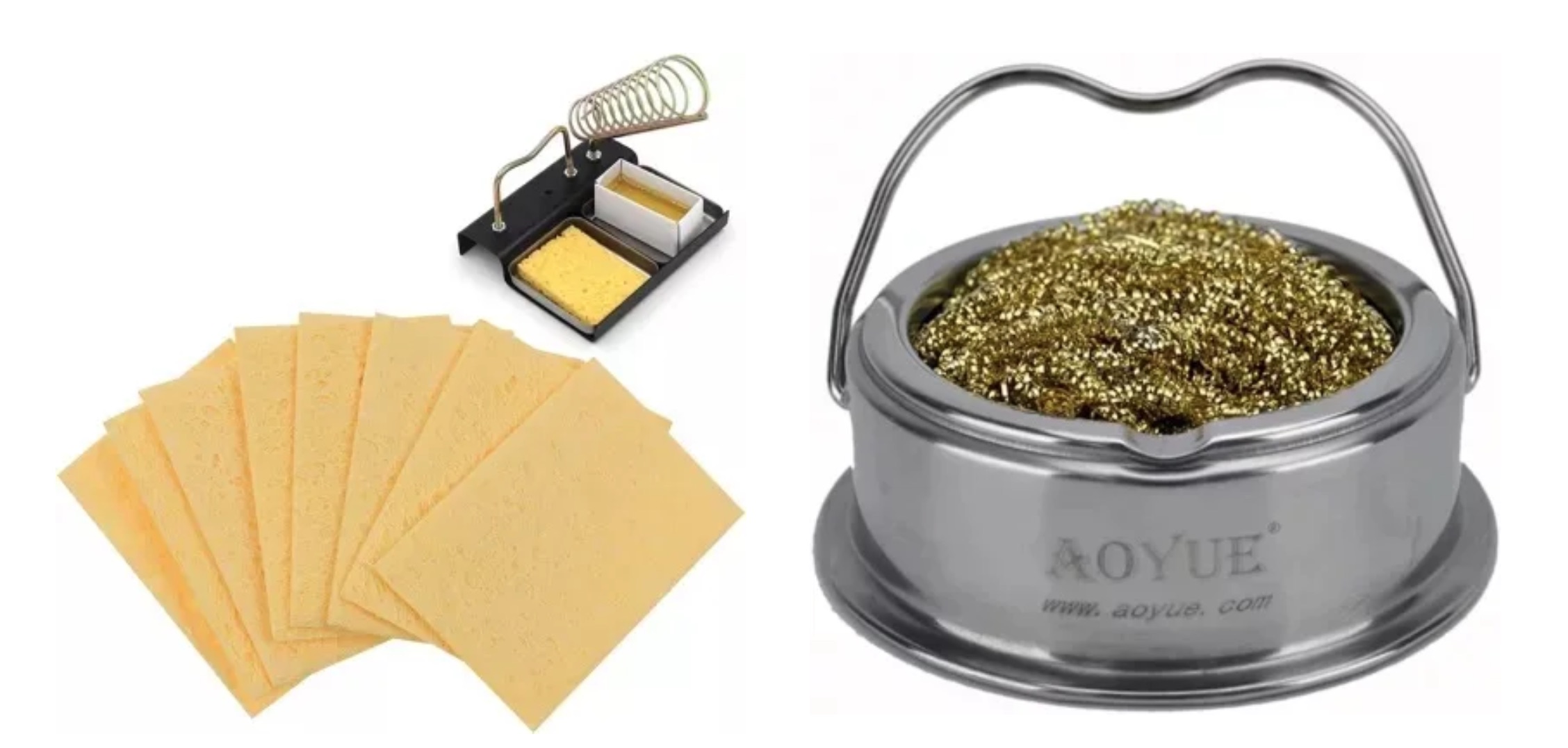

To clean a tip, makers have a number of options available to them. The first, and most ancient, is the faithful soldering sponge that is moistened with water, and the tip brushed against the sponge to remove debris. While this does work, the use of water can induce thermal shock into the tip, further damaging it.

Instead, a much better cleaning method is to use a brass soldering sponge, as these not only remove debris, but don’t dramatically change the temperature of the soldering iron tip. To use these sponges, a soldering iron merely needs to stab the sponge a few times before the tip will look brand new.

Once all soldering has been done, and it’s time to pack up, it is essential that a small amount of solder is melted onto the top and allowed to remain. This ball of solder at the end of your tip will protect the tip from oxidation while in storage.

Next - How To Solder