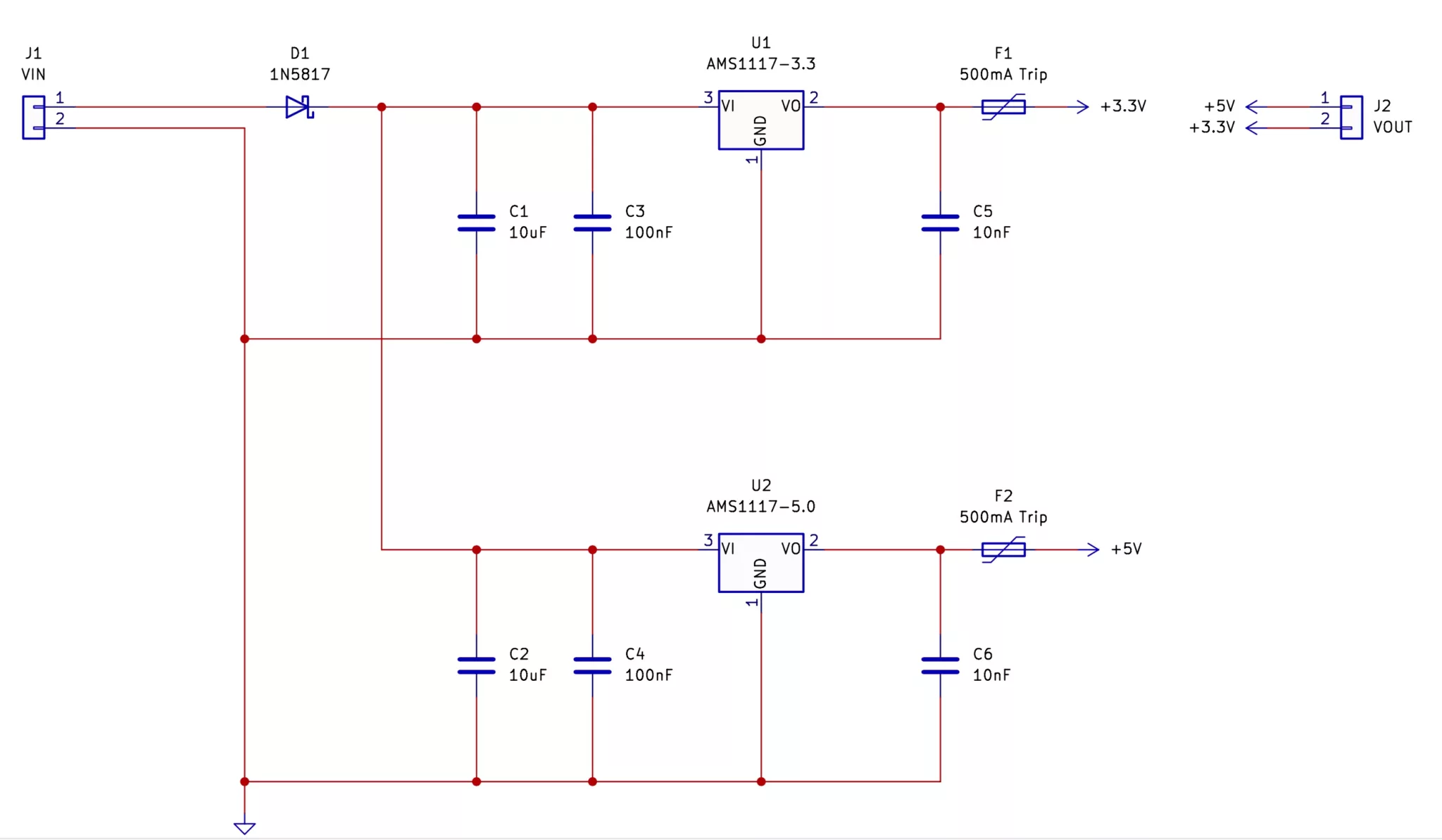

The Simple Power Module SMD Trainer kit is a module that provides two regulated output voltages from a single input voltage. These two voltages are 5V and 3.3V, and can be used to power most maker circuits including microcontrollers, sensors, shields, and add-ons. Furthermore, each regulated output has its own fuse, which protects the regulators and the circuit being powered.

As the aim of this kit is to introduce you to SMD soldering, the theory behind the circuit will not be covered here.

Besides the obvious use of SMD training, the Simple Power Module can be used in many different projects. For example, the Simple Power Module SMD can be used for converting a 9V battery into a 3.3V source suitable for a Raspberry Pi Pico microcontroller. The module could also be used for providing 5V to a micro servo and a 3.3V source for a sensor.

The spacing between the input and output have been designed to fit across a breadboard, meaning that this module is breadboard friendly. As such, you can use this module with breadboard designs, thereby allowing for reuse and modification.

| Component | PCB Reference | Quantity | Looks Like |

|---|---|---|---|

| AMS1117 3.3V Regulator | U1 | 1 |  |

| AMS1117 5V Regulator | U2 | 1 |  |

| 10nF 0805 Ceramic Capacitor | C5, C6 | 2 |  |

| 100nF 0805 Ceramic Capacitor | C3, C4 | 2 |  |

| 10uF 0805 Ceramic Capacitor | C1, C2 | 2 |  |

| SMD Poly Fuse | F1, F2 | 1 |  |

| 1N5817 Diode SMD | D1 | 1 |  |

| 4 Way Straight Connector | J1, J2 | 1 |  |

To learn more about how to solder electronic components, download the Electronics Construction Manual free using the button below

Electronics Construction Manual

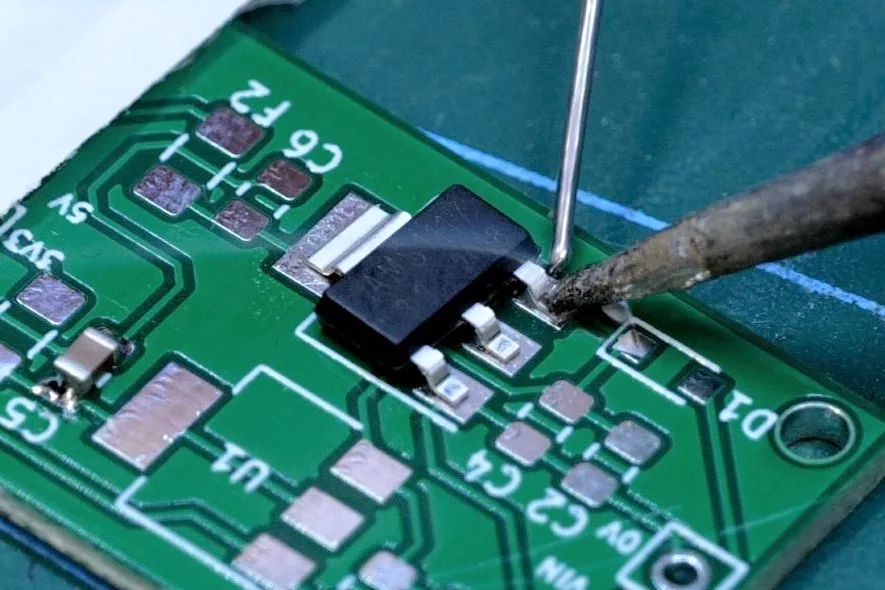

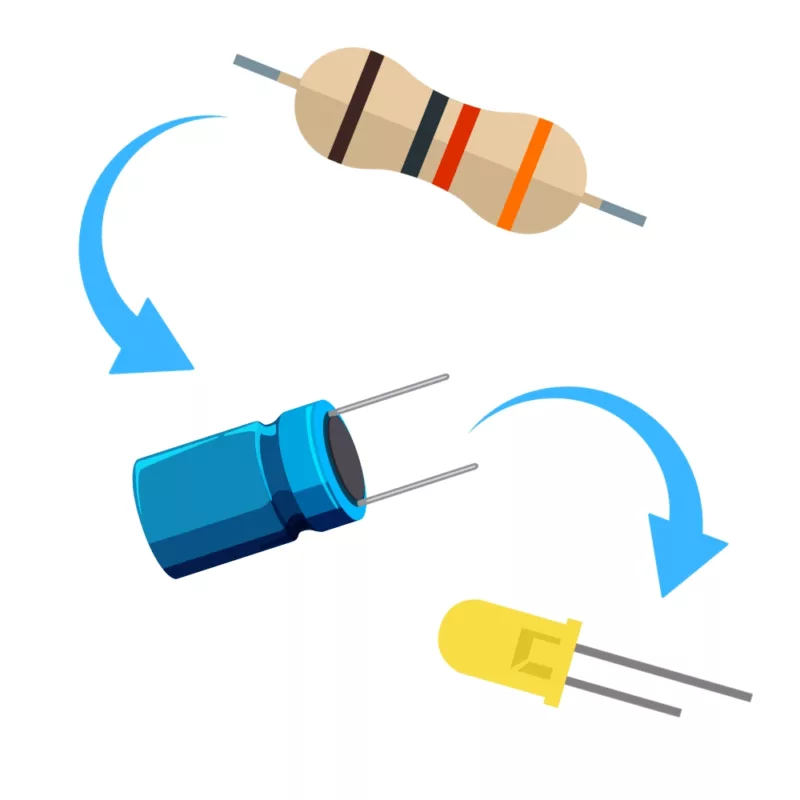

When soldering components, it is essential that you do so in a particular order, so that it is easy to add components and get to their legs. Generally, you always start with the smaller components (such as resistors and capacitors), before moving onto the larget parts (potentiometers and ICs).

Soldering Guide

To help keep the board stable when soldering, you can download a free STL model of a basic jig that can be 3D printed with all common 3D printers. Watch out for the mounting hole pins as they may be vulnerable to snapping if using a low infill density, low wall thickness, or thick layer heights. Additionally, do not use hot air to solder the PCB when using the jig as you will melt the jig.

Coming Soon...